Cost estimation

Cost estimation is the process of finding cost of a product before it

actually manufactured. To run any profitable business, need to estimate and

determine accurate and competitive price of a product. Person who prepare estimate is known

as “Estimator”

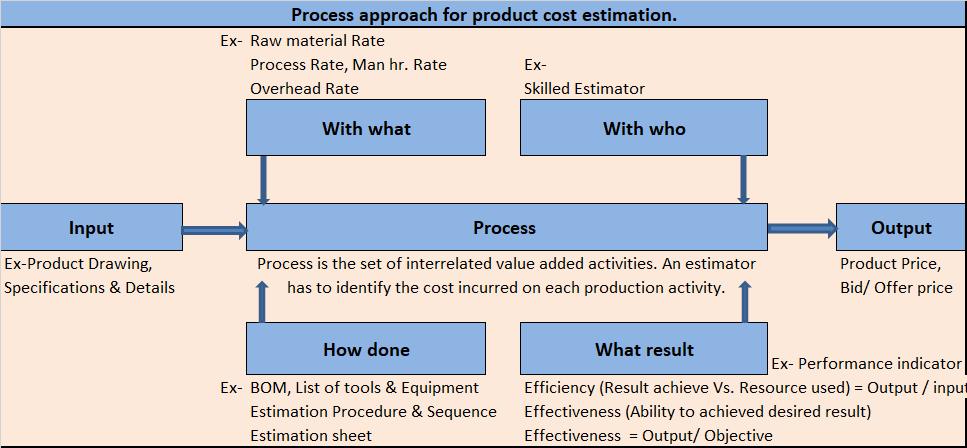

Process approach for product cost estimation

Different organization has different

process and product. Process is set of interrelated or interacting activities which transforms input into output. Identification and management of cost estimation processes within an organization (interaction between processes) is called process approach. An estimator role is to identify cost incurred on each activity.

|

Process approach for estimation and costing |

Aim of

product estimation:

- Filling tender, request for

quotation and enquiry.

- To determine material cost, labour

cost, cost of bought out parts, cost of tools and equipment.

- To determine overhead charges

including packaging transportation and selling cost.

- To decide sales price.

- To compare cost of product with market price.

- Help modification in material, process or design, if price is higher than market price

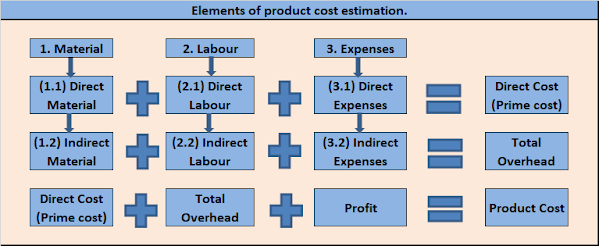

Element of Product cost estimation:

There are three main element of product cost estimation.

- Material Cost: Further divided in direct material cost & indirect material cost.

- Labour cost: Further divided in

direct labour cost & indirect labour cost.

- Expenses: Further divided in direct expenses & indirect expenses.

Refer the below table

|

| Elements of cost for costing and estimation |

Direct

cost/ Prime Cost= Direct material cost + Direct labour cost + Direct expenses

Overhead = Indirect material cost + Indirect labour cost + Indirect expenses (included factory expenses, Office & administration expenses, Selling expenses, Distribution expenses etc.)

Product cost= Direct cost + Overhead + Profit.

Product cost estimation procedure:

- Drawing Review: Availability of all drawing from main assemble to part level. Availability of all details and specification.

- Feasibility review: Availability of raw material as per specified grade, tools and machinery, skilled worker, process feasibility etc.

- Review specific customer requirement

and specific commercial terms if any.

- Review packaging and transportation

requirement.

- Prepare bill of material.

- Prepare method and sequence of operation.

- Prepare list of machine and manpower required for production.

- Estimate operation time required for each process and activity.

- Decide any parts to be made in-house

or outsource.

- Calculate material cost.

- Calculate cost of outsource and bought out parts.

- Calculate labour cost.

- Calculate Direct cost = Direct

material cost + Direct labour cost + Direct expenses

- Calculate Product cost= Direct cost

+ Overhead + Profit

1.

0 comments:

Post a Comment